So I've been playing with ABS "adaptations" under threshold braking conditions. I have my DS2500 pads back on since their friction mu is far more consistent at varying temperatures I can actually reach on the street.

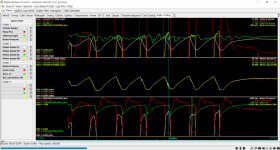

"Brake Booster" absolutely affects how much heat gets put into the front brakes. It does NOT have to do with overall brake vacuum boost as others think. Because I can log the vacuum in the booster, I have these overlaid. You can see vacuum builds VERY slowly. I think people who perceive a difference at idle at just pumping the pedal a ton and depleting vacuum so it feels stiffer:

View attachment 283826

That said, testing under HARD threshold braking found some differences:

Lower numbers *seem* to put more force forward. Rear rotor temps remained constant when checked through the 3 tests where Brake Booster was changed. Not publishing any specific numbers yet because honestly I think my very first "control" test (BB 5, HBB 8) was flawed. It was first and showed much lower front rotor temps than BB settings both higher and lower, I think it just needs to be tested again in the middle or end of other tests. Also I was an idiot and did 6 stops on 2 of the other 3 tests. There is a definite difference in feel between 0 and 8 "brake booster" with no other differences under threshold braking.

I also did one test with "Hydraulic Brake Booster" which affect rear bias as others have alluded to.

I found a modeled "brake overheating" PID and interestingly enough... it does some goofy stuff on one log (not the abrupt pressure drop, and accompanying longitudal Gs).. and nothing (or basically nothing) on another.

This was BB 0 (stock 5), and HBB 8 (stock). You can see the yellow vertical line where the brake overheating goes from 0 to 1.

View attachment 283823

BB 8, HBB 8 (stock). Brake overheating happened at the very end as I got off the brake. Nothing conclusive from that here.

View attachment 283824

BB 5 (stock), HBB 0 (stock is 8) - you can see the rear wheels locking up here. Interestingly the "brake overheating" flipped from false to true (0 to 1), with no real notable change in pressure.

View attachment 283825

So this will require a bit of fiddling with on track, I suspect with the DS3.12/1.11 combo I'll try BB 4 or 5 and HBB 6 as a starting point next time.

I suspect the corresponding change in pedal "feel" may be the ABS internally absorbing some pressure to keep in reserve or something to that effect. Perhaps the 0-10 numbers are % based "factors" to decrease pressure on the individual F/R wheel circuits?

Continental has a still-active patent that might shed some light on how the ABS internal valves work:

https://patents.google.com/patent/US8751129

There are also some other adaptations worth looking into that nobody really has played with... the full list is here (for my car at least):

IDE00001-Production mode,not active ,3

IDE00252-Brake system vacuum pump,5 ,1 <-- I have played with this one with no observable changes in measured vacuum, I suspect it may point to type of vacuum pump installed?

IDE00820-Activating and deactivating all development messages,0 ,1 <--- Maybe play with and see if it gives diagnostic info on the dash or radio, just maybe?

IDE02332-Deactivate production mode,Deactivating ,3

IDE03659-Roller test bench mode,Manual activation: possible ,1

IDE04456-Brake disk drying,Medium ,1

IDE04508-Hydraulic brake booster,8 ,1

IDE04643-Overboost in brake system,activated ,1

IDE04774-Vehicle and trailer stabilization,not activated ,1

IDE04939-Tire Pressure Monitoring System (TPMS),2 ,1

IDE04949-Engine drag torque control,activated ,1

IDE04951-Brake Boost,5 ,1

IDE04952-Braking torque boost for distance regulation,3 ,1

IDE05055-Hydraulic brake assistant,normal ,1

IDE05057-Brake prefill,activated ,1

IDE05161-Straight ahead brake stabilization,not activated ,1

IDE05286-Expanded electronic differential lock,Weak ,1 <--- This proved to help as it is for disabling the brake murdering stability control. It is actually currently "off".

IDE06425-Dynamometer mode: functional,not activated ,1

IDE07006-Tire pressure monitoring display: tire selection,2 ,1

IDE07292-Brake pre-filling,not completed successfully ,1

IDE07565-ABS in lower speed range,activated ,1 ????? Might be worth playing with

IDE07848-Thresholds for brake performance,activated ,1 <--- This I've not heard of anyone screwing with, and may be worth testing? Maybe hopeful that it removes the "brake overheating" flag?

IDE12030-Rough road optimization,activated ,1 <--- People swear this has to do with traction control. It doesn't. It is logic used to determine if the car is driving over a bumpy road or not so that the ECU doesn't detect false misfires. Leave it activated.

MAS00122-Electronic Stability Program,not activated ,1

MAS00970-Running manufacturer number,activated ,1

MAS01299-Offroad,0 ,1

MAS02080-XCP calibration protocol,not activated ,1

MAS02138-Hill-start assistant,normal ,1

ENG130301-Developer_Function_121,not activated ,1