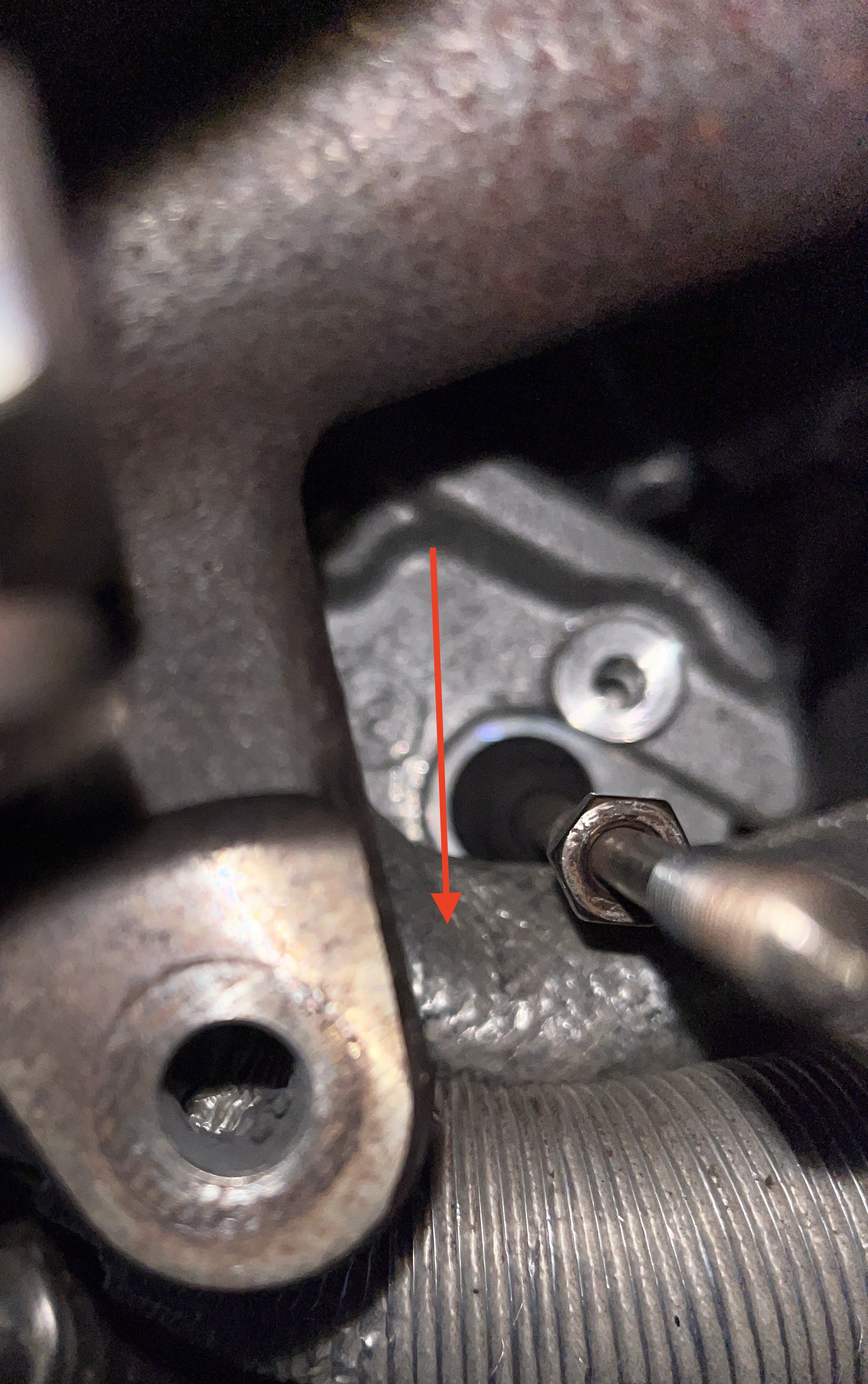

Got this job finished. I unbolted the driveshaft and downpipe and moved them aside to get access to the actuator from below. The oil return line blocks straight-on access to the actuator bolt closer to the firewall, as seen in the photo in the OP. I used a mini-ratchet with a T30 bit to loosen the remaining bolt. That seemed easier than removing the oil line.

View attachment 303743

I bought a Unitronic WG actuator that came with stainless bolts (10mm wrench size). I used those instead of the Torx bolts. A 10mm offset wrench was helpful for getting the firewall side tight. I cut a small piece of bike inner tube to get a better grip on the actuator rod for adjustment rather than using a wrench/vise-grip, which worked well.

The swivel on the WG shaft that the actuator connects to was binding. There are no signs of corrosion. I'm convinced that the mechanical resistance caused the original actuator to fail (or at least more quickly). I worked the swivel through its range a bunch of times until it freed up, then packed it with high-temp antiseize (Loctite 41205).

I did a lot of learning the hard way on this job. Given that the car is 5 years old with almost 90k miles, I probably should have upgraded the turbo. Removing the turbo might have been less labor.

Seems like the turbo spools quicker at low RPM, so maybe the old actuator had partly failed for some time.