staying_tuned

Drag Racing Champion

- Location

- Poconos

- Car(s)

- 2016 Mark 7 Golf R

So thanks to the forum and a few prompt responses from Gilbert at PR my MPI install wen't smoothly. One thing I couldn't mentally grapple is why the injectors aren't seating in what appears to be a perfectly cupped seat with guide notch and grove.

Anyone with the PR kit knows what I mean and I'm wondering if this is the case with the CTS, Iroz and APR kit as well. In the first photo you can see the rail mounting point (upper left) is fully seated on the manifold posts yet the injectors have a good 1/8" to go before being fully seated.

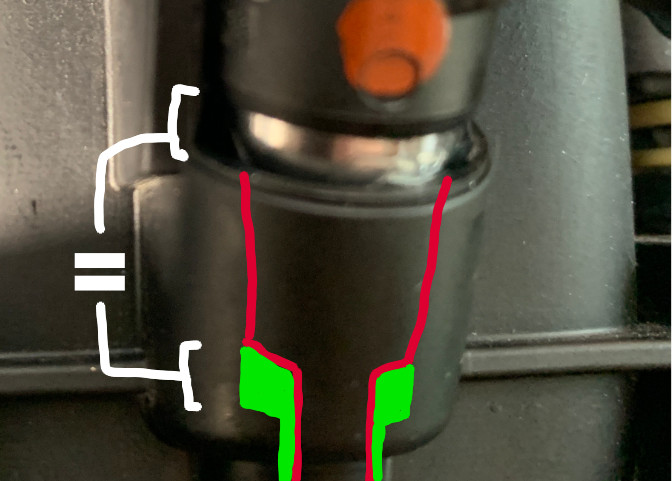

Aside from what can visually be seen here, the base of the injector with the bottom cupped shaped gasket (see pic) and bottom of these injector holes appear to be designed to mate together like two cups stacked. With the space, there is no contact, just a void of air. I'm worried less about a leak than I am about the impact this has on air flow and the resulting spray pattern. With the nozzle being 1/8" or 1/4" higher in the manifold there must be cases where actual drips of fuel are formed along the inside of the manifold as opposed to a clean mist. See second photo where I've represented the air pocket. I'd also wager that the upper gasket alone was not designed to hold back 30+ psi long term, the two gaskets are most likely designed to work together.

Is this the case with the CTS kit as well?

I've got an email out to Iroz & APR to see if they'd sell just their rail. I'd love to see photos of how the injectors are seated post install but their install guides only show a top down view, not the actual final seating position.

Does anyone know if any rail other than PRs seat the injectors fully? Call me paranoid but I'm making it a point to scrutinize everything along the way and this just seems like a potential area of concern. Thoughts?

Thanks in advance!

Follow-up info: APR’s rail is $194 and part number Z1002866. Awaiting word back from Iroz.

Fully seated rail yet injector floating high 1/8" or more:

Resulting pocket created:

Injector gaskets with bottom one being nulled out by gap:

Anyone with the PR kit knows what I mean and I'm wondering if this is the case with the CTS, Iroz and APR kit as well. In the first photo you can see the rail mounting point (upper left) is fully seated on the manifold posts yet the injectors have a good 1/8" to go before being fully seated.

Aside from what can visually be seen here, the base of the injector with the bottom cupped shaped gasket (see pic) and bottom of these injector holes appear to be designed to mate together like two cups stacked. With the space, there is no contact, just a void of air. I'm worried less about a leak than I am about the impact this has on air flow and the resulting spray pattern. With the nozzle being 1/8" or 1/4" higher in the manifold there must be cases where actual drips of fuel are formed along the inside of the manifold as opposed to a clean mist. See second photo where I've represented the air pocket. I'd also wager that the upper gasket alone was not designed to hold back 30+ psi long term, the two gaskets are most likely designed to work together.

Is this the case with the CTS kit as well?

I've got an email out to Iroz & APR to see if they'd sell just their rail. I'd love to see photos of how the injectors are seated post install but their install guides only show a top down view, not the actual final seating position.

Does anyone know if any rail other than PRs seat the injectors fully? Call me paranoid but I'm making it a point to scrutinize everything along the way and this just seems like a potential area of concern. Thoughts?

Thanks in advance!

Follow-up info: APR’s rail is $194 and part number Z1002866. Awaiting word back from Iroz.

Fully seated rail yet injector floating high 1/8" or more:

Resulting pocket created:

Injector gaskets with bottom one being nulled out by gap:

Last edited: