YamR1rider

Drag Racing Champion

- Location

- Tampa, FL

- Car(s)

- 2017 GTI Sport DSG

Did the above this week on our 143k miles 1.8 TSi, reasons being random EPC lights once every week or two and as described by daughter, 'shuddering', aka misfires/EPC light+limp mode (OBDEleven said 'cylinder pressure to high' and resultant 'hide cylider', plus very occasional (once per 2-3 months say) temperature shooting all the way into the red and resultant EPC/limp mode/pull over now etc (OBDEleven 'poor coolant flow'). And one time apparently, 'very limp' mode where there car would barely move off a traffic light.

Yet in all cases, a quick turn off/on would clear all and car would run fine, misfires gone, temps instantly normal ....until the next time which could be days to weeks away. Plus there was an oil leak which seemed to be coming from the cooler and a slight internal cooler leak (tiny amount of oil in coolant).

Goes without saying I'd already done the routine easy stuff like plugs, coils, injector cleaner etc. So, I decided to 'parts cannon' it,'while I'm in there' style.....thankfully, no 'labor cannon' required, DIYed the lot. Didn't find it *too* bad of a job....but there were some curse worthy moments and bolt battles encountered. In summary, for anyone having a go at similar in future:

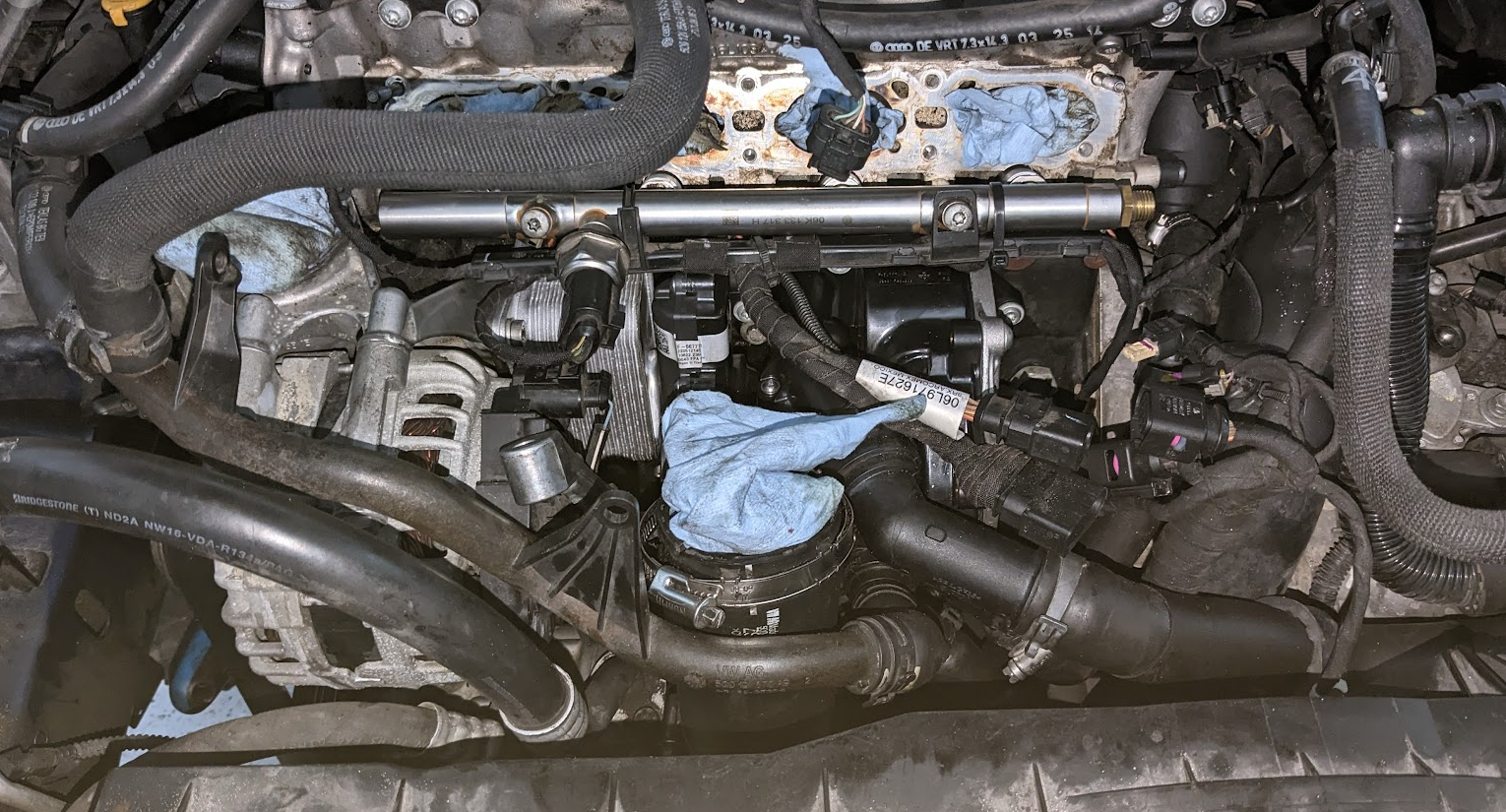

1. Manifold off - really not that big of a deal. Worst of it for me was paranoia of breaking the six-eight electrical connectors to be disconnected, which after 8 years, were fused together and the plastic brittle and nasty. Silicone spray, patience and research into how each different connector locking mechanism works helps. Only one real casualty - cam sensor - just crumbled in my hands the plastic was so rotten. Hadn't counted on needing a new one and could have probably taped/glued the break back together somehow....but managed to get one locally (from autozone) so didn't hold job up too much and as much as I'd have preferred an OEM one, this 'duralast' seems to be fine. Other mildly tricky bits with the manifold included the front bracket with its hard to get at M10 triplesquare, and separately, the bottom hard fuel line to fuel rail nut - needed to cut a cheap harbor freight 17mm in half to get that off. *Note anyone watching humble mechanics way of doing it (which is otherwise excellent as he really removes the minimum amount of stuff to get the manifold off...others like FCP Euro...while they sure are comprehensive, I thought they were going to start stripping the cylinder head, ,maybe remove the engine entirely while they were at it lol), "get the manifold off without removing the hard fuel line first, or conversely put the hard line on before the manifold" - nope - that could only potentially work on later Mk7.5s like his yellow R (or my own 2017 GTI) where they seemingly changed out the two top outer manifold studs and nuts to bolts which will give some left to right adjustment of the manifold. Otherwise, the hard fuel line must come off first and go back on last. What you could do, while you are at it, is replace the nut/studs for bolts like the later cars to make the job easier in future.

Manifold off... fairly simple tbh

Tool of champions

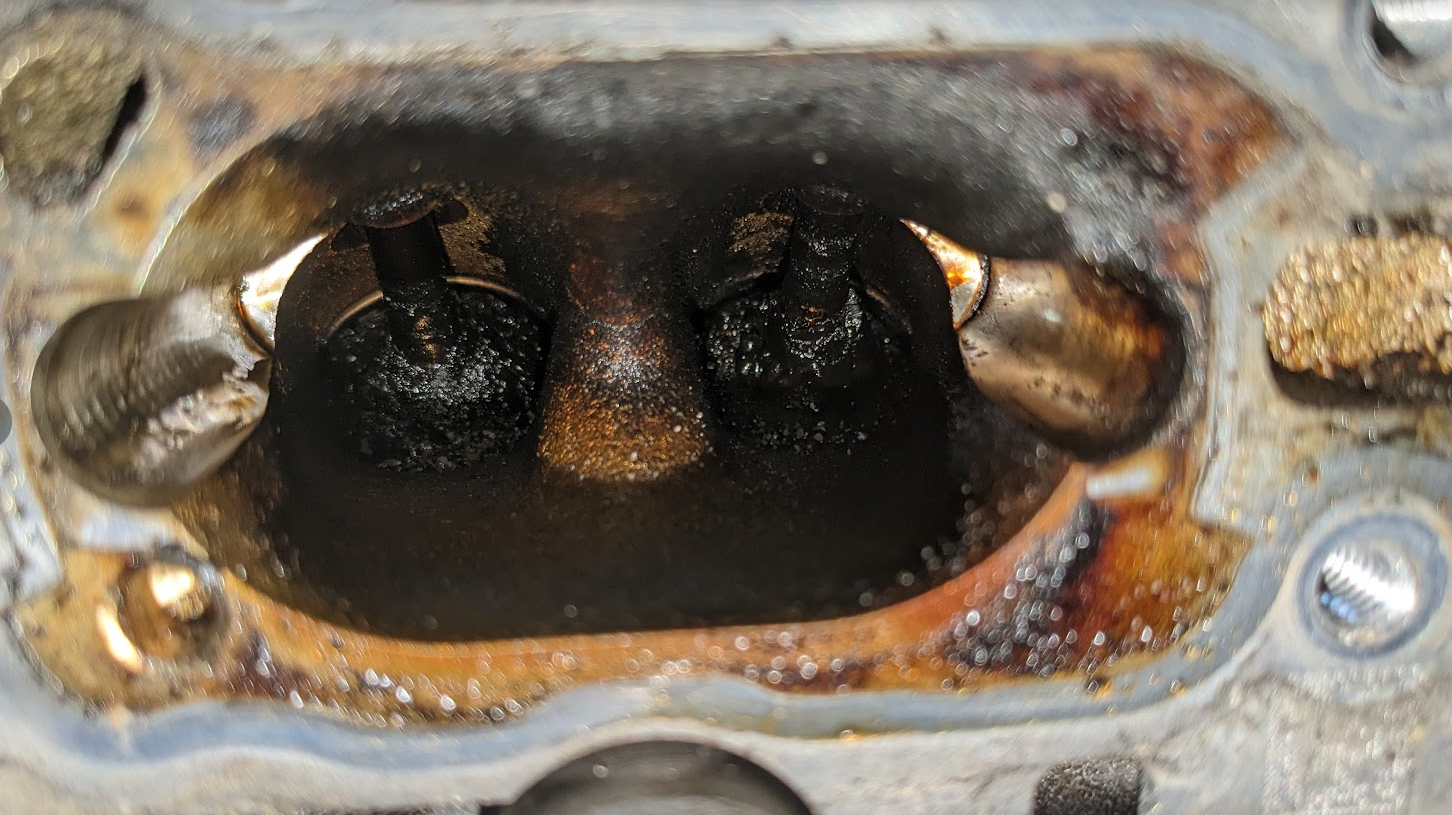

2. DIY carbon cleaning - If you don't walnut blast its never going to be immaculate but I found that closing the valves, flooding with carb cleaner and going at it with a fistful of cable ties makes it a lot better than it was. Quick note, I'd recommend you cut the smooth tapered ends off the cable ties as they have a tendency to break off. I blew a broken-off end out with my compressed air....but best not one go unnoticed and then drop down into the cylinder when you rotate the crank for the next one. Otherwise, jabbing away with the ties is pretty much risk free and combined with carb cleaner, does loosen up plenty of crap....then hold a rag over and blow out with compressed air at the end. Rinse/repeat at least three times....I should have have a couple more go rounds//let soak longer really, but hey, they ended up much better than before!

Pretty gunked up...perhaps not as bad as could have been....no idea if they have ever been done before or not

Pic doesn't really do it justice, I think I took this after 2 go rounds but much improved. Time and extra scraping would have helped but I wanted to crack on with the below....

3. Injector replacement - bought OEM Bosch ones from FCP Euro, saved a lot over branded VW for same thing. Even though new injectors come with seals....make sure you do spend the extra 9 bucks per cylinder on the fitting kits. The new injectors don't come with the 'hold off/ injector bore spacers' (or whatever they are called...little plastic rings with three prongs them), nor the metal top tension rings. You could reuse these parts....but in my case one of the 'bore spacers' broke on removal so I was happy to have the new ones on hand, plus the top tension rings - you don't know if the oldun's have become over compressed. That all said, replacing the injectors was the easiest part of this job. When I pulled the fuel rail, 3 came out along with the rail, and the last one came out with minimal pick/by hand persuasion, no $100 fancy slide hammer kit required. New ones pushed in by hand and wiggling, no hassles.

Pretty sure these were original 140k mile injectors. Pretty carboned. My moneys on one or more of these (rather than the grubby valves) for the intermittent faults

Old injectors as they came out. Note the broken 'pronged bore spacer thing' just above the top right one. A prong broke off when removed the spacer from the injector, very fragile/brittle plastic, hence why I'd recommend having the fitting kits on hand rather than trying to reuse those parts.

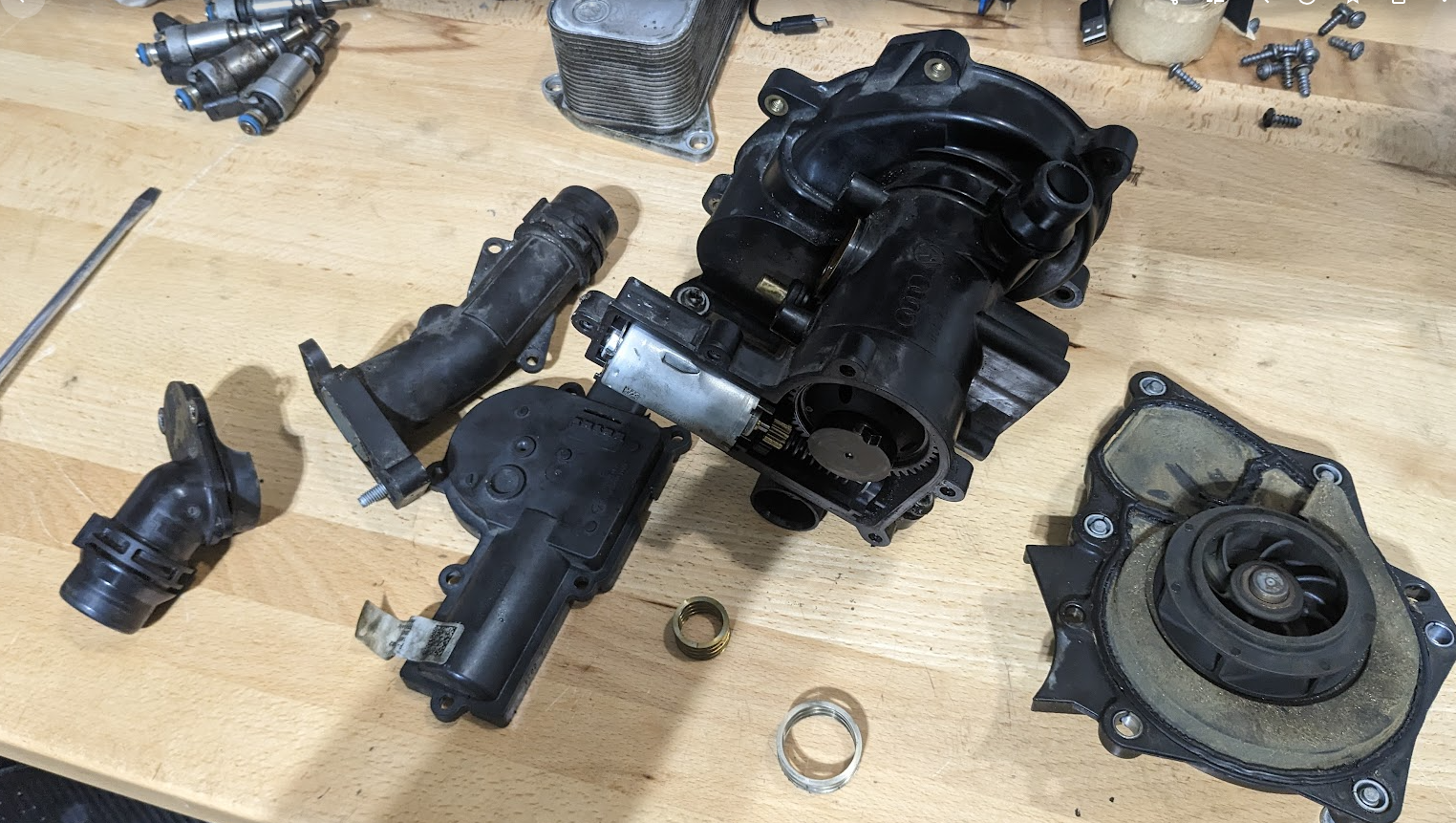

4. Water Pump - The one coming off this car was the original (2014 date stamp)...amazing eh, its done 140k...and wasn't actually leaking!!, Only reason I took it off was due to the dodgy temperature control actuator, (as I understand it, this is built into the waterpump /tstat module, there are also temperature sensors on the transmission side of the cylinder head and one down on the bottom coolant hose...if it turns out the be the other ones so be it (pretty easy fixes both) but I couldn't do all this work and leave this old pump in there!). It was a G revision. As replacement, I bought an INA OEM (VW/Audi logo scrubbed off) from FCP Euro. A massive pain in the ass for this job was getting off the T30s holding the drive belt cover....in hindsight and if doing it again, I will take off another couple of coolant pipes off as its blind and so very tight to get just a socket in, let alone a ratchet. Cue skinned and bruised knuckles, and scratched/minor cut fingers galore. Same goes for the bottom two water pump bolts....blind and horrible, you just have to persevere and try lots of different length 1/4 extensions etc. (you could take the fan housing out I guess which would give a bit more room....but to me that looked like even more hassle with more breaky clips, so didn't bother). Also on replacement, very very carefully watch the union that goes between pump and oil cooler...it has a tendency to pop out and twist sideways slightly......my huge mistake on this entire job was thinking it was in straight when it wasn't. Was alerted to this fact when I went to refill coolant (using my vacuum filler, wouldn't hold pressure..... I did get some water in though and sure enough, there found the union leaking. And thus.....had to deal with taking the f@@king pump off and on again. Plus the infernal waterpump drive cover bolts. Faster second time round, but this was not a happy time!!

Cracked this old thing apart for fun....8 year old 140k+ miles no leaks...who knows maybe its not even this sensor that's the cause of this issue....but while in there it had to go. RIP rare 8 year old/no leaks MQB water pump....a rare breed indeed!

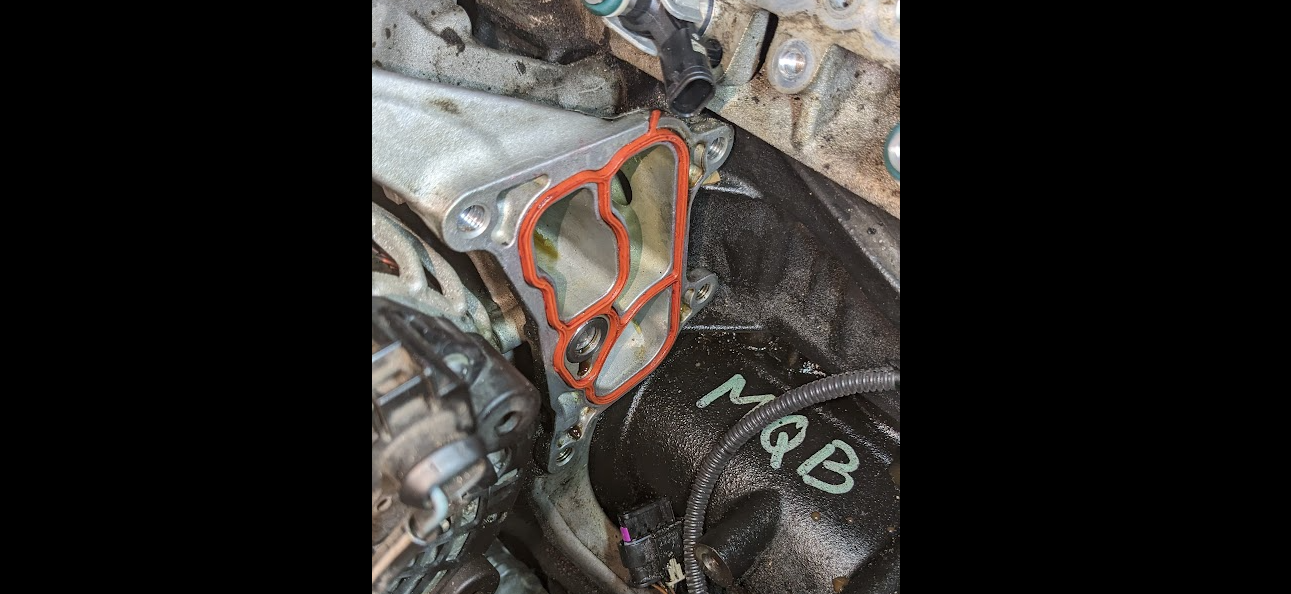

5. Oil Cooler - with water pump off, not too difficult to get at the four bolts and take off. Mine had slight internal leak and larger external leak. Clearly the issue was the old brittle seal - but while there I replaced the cooler with a pattern UroParts one - took a bit of a chance here (where I'd never do with critical components such as injectors or water pump).....but its not a complex component for the aftermarket, and seems perfectly fine. Original also seemed fine after 140k miles to be fair - Think I will clean it up, run some de-gunker through it and keep it for a spare. Leak fixed, happy days.....at least...I think. If in the coming days it transpires there is still some leakage, next up will be to unmount alternator and a/c compressor then pull the oil filter housing bracket to get at the other back-side seal. At least that bit will be doable without taking manifold back off etc. should it come to it.

Been leaking a while this one

Nice fresh seal

6. Conclusion - Despite some tribulations, got it all back together....car cranked a bit longer than usual first time as fuel was priming through but then struck up nicely.....and the car is running beautifully - so super happy.... as of 19 Feb have even given it the berries up and down a favorite bit of 'track' several times, super smooth the entire rev range!

Next up at some point will be to refresh the worn shocks/struts which are also probably 140k originals too....its in perma 'super comfort/sofa mode' just now lol!

Yet in all cases, a quick turn off/on would clear all and car would run fine, misfires gone, temps instantly normal ....until the next time which could be days to weeks away. Plus there was an oil leak which seemed to be coming from the cooler and a slight internal cooler leak (tiny amount of oil in coolant).

Goes without saying I'd already done the routine easy stuff like plugs, coils, injector cleaner etc. So, I decided to 'parts cannon' it,'while I'm in there' style.....thankfully, no 'labor cannon' required, DIYed the lot. Didn't find it *too* bad of a job....but there were some curse worthy moments and bolt battles encountered. In summary, for anyone having a go at similar in future:

1. Manifold off - really not that big of a deal. Worst of it for me was paranoia of breaking the six-eight electrical connectors to be disconnected, which after 8 years, were fused together and the plastic brittle and nasty. Silicone spray, patience and research into how each different connector locking mechanism works helps. Only one real casualty - cam sensor - just crumbled in my hands the plastic was so rotten. Hadn't counted on needing a new one and could have probably taped/glued the break back together somehow....but managed to get one locally (from autozone) so didn't hold job up too much and as much as I'd have preferred an OEM one, this 'duralast' seems to be fine. Other mildly tricky bits with the manifold included the front bracket with its hard to get at M10 triplesquare, and separately, the bottom hard fuel line to fuel rail nut - needed to cut a cheap harbor freight 17mm in half to get that off. *Note anyone watching humble mechanics way of doing it (which is otherwise excellent as he really removes the minimum amount of stuff to get the manifold off...others like FCP Euro...while they sure are comprehensive, I thought they were going to start stripping the cylinder head, ,maybe remove the engine entirely while they were at it lol), "get the manifold off without removing the hard fuel line first, or conversely put the hard line on before the manifold" - nope - that could only potentially work on later Mk7.5s like his yellow R (or my own 2017 GTI) where they seemingly changed out the two top outer manifold studs and nuts to bolts which will give some left to right adjustment of the manifold. Otherwise, the hard fuel line must come off first and go back on last. What you could do, while you are at it, is replace the nut/studs for bolts like the later cars to make the job easier in future.

Manifold off... fairly simple tbh

Tool of champions

2. DIY carbon cleaning - If you don't walnut blast its never going to be immaculate but I found that closing the valves, flooding with carb cleaner and going at it with a fistful of cable ties makes it a lot better than it was. Quick note, I'd recommend you cut the smooth tapered ends off the cable ties as they have a tendency to break off. I blew a broken-off end out with my compressed air....but best not one go unnoticed and then drop down into the cylinder when you rotate the crank for the next one. Otherwise, jabbing away with the ties is pretty much risk free and combined with carb cleaner, does loosen up plenty of crap....then hold a rag over and blow out with compressed air at the end. Rinse/repeat at least three times....I should have have a couple more go rounds//let soak longer really, but hey, they ended up much better than before!

Pretty gunked up...perhaps not as bad as could have been....no idea if they have ever been done before or not

Pic doesn't really do it justice, I think I took this after 2 go rounds but much improved. Time and extra scraping would have helped but I wanted to crack on with the below....

3. Injector replacement - bought OEM Bosch ones from FCP Euro, saved a lot over branded VW for same thing. Even though new injectors come with seals....make sure you do spend the extra 9 bucks per cylinder on the fitting kits. The new injectors don't come with the 'hold off/ injector bore spacers' (or whatever they are called...little plastic rings with three prongs them), nor the metal top tension rings. You could reuse these parts....but in my case one of the 'bore spacers' broke on removal so I was happy to have the new ones on hand, plus the top tension rings - you don't know if the oldun's have become over compressed. That all said, replacing the injectors was the easiest part of this job. When I pulled the fuel rail, 3 came out along with the rail, and the last one came out with minimal pick/by hand persuasion, no $100 fancy slide hammer kit required. New ones pushed in by hand and wiggling, no hassles.

Pretty sure these were original 140k mile injectors. Pretty carboned. My moneys on one or more of these (rather than the grubby valves) for the intermittent faults

Old injectors as they came out. Note the broken 'pronged bore spacer thing' just above the top right one. A prong broke off when removed the spacer from the injector, very fragile/brittle plastic, hence why I'd recommend having the fitting kits on hand rather than trying to reuse those parts.

4. Water Pump - The one coming off this car was the original (2014 date stamp)...amazing eh, its done 140k...and wasn't actually leaking!!, Only reason I took it off was due to the dodgy temperature control actuator, (as I understand it, this is built into the waterpump /tstat module, there are also temperature sensors on the transmission side of the cylinder head and one down on the bottom coolant hose...if it turns out the be the other ones so be it (pretty easy fixes both) but I couldn't do all this work and leave this old pump in there!). It was a G revision. As replacement, I bought an INA OEM (VW/Audi logo scrubbed off) from FCP Euro. A massive pain in the ass for this job was getting off the T30s holding the drive belt cover....in hindsight and if doing it again, I will take off another couple of coolant pipes off as its blind and so very tight to get just a socket in, let alone a ratchet. Cue skinned and bruised knuckles, and scratched/minor cut fingers galore. Same goes for the bottom two water pump bolts....blind and horrible, you just have to persevere and try lots of different length 1/4 extensions etc. (you could take the fan housing out I guess which would give a bit more room....but to me that looked like even more hassle with more breaky clips, so didn't bother). Also on replacement, very very carefully watch the union that goes between pump and oil cooler...it has a tendency to pop out and twist sideways slightly......my huge mistake on this entire job was thinking it was in straight when it wasn't. Was alerted to this fact when I went to refill coolant (using my vacuum filler, wouldn't hold pressure..... I did get some water in though and sure enough, there found the union leaking. And thus.....had to deal with taking the f@@king pump off and on again. Plus the infernal waterpump drive cover bolts. Faster second time round, but this was not a happy time!!

Cracked this old thing apart for fun....8 year old 140k+ miles no leaks...who knows maybe its not even this sensor that's the cause of this issue....but while in there it had to go. RIP rare 8 year old/no leaks MQB water pump....a rare breed indeed!

5. Oil Cooler - with water pump off, not too difficult to get at the four bolts and take off. Mine had slight internal leak and larger external leak. Clearly the issue was the old brittle seal - but while there I replaced the cooler with a pattern UroParts one - took a bit of a chance here (where I'd never do with critical components such as injectors or water pump).....but its not a complex component for the aftermarket, and seems perfectly fine. Original also seemed fine after 140k miles to be fair - Think I will clean it up, run some de-gunker through it and keep it for a spare. Leak fixed, happy days.....at least...I think. If in the coming days it transpires there is still some leakage, next up will be to unmount alternator and a/c compressor then pull the oil filter housing bracket to get at the other back-side seal. At least that bit will be doable without taking manifold back off etc. should it come to it.

Been leaking a while this one

Nice fresh seal

6. Conclusion - Despite some tribulations, got it all back together....car cranked a bit longer than usual first time as fuel was priming through but then struck up nicely.....and the car is running beautifully - so super happy.... as of 19 Feb have even given it the berries up and down a favorite bit of 'track' several times, super smooth the entire rev range!

Next up at some point will be to refresh the worn shocks/struts which are also probably 140k originals too....its in perma 'super comfort/sofa mode' just now lol!

Last edited: