Let's just get this party started now I guess.

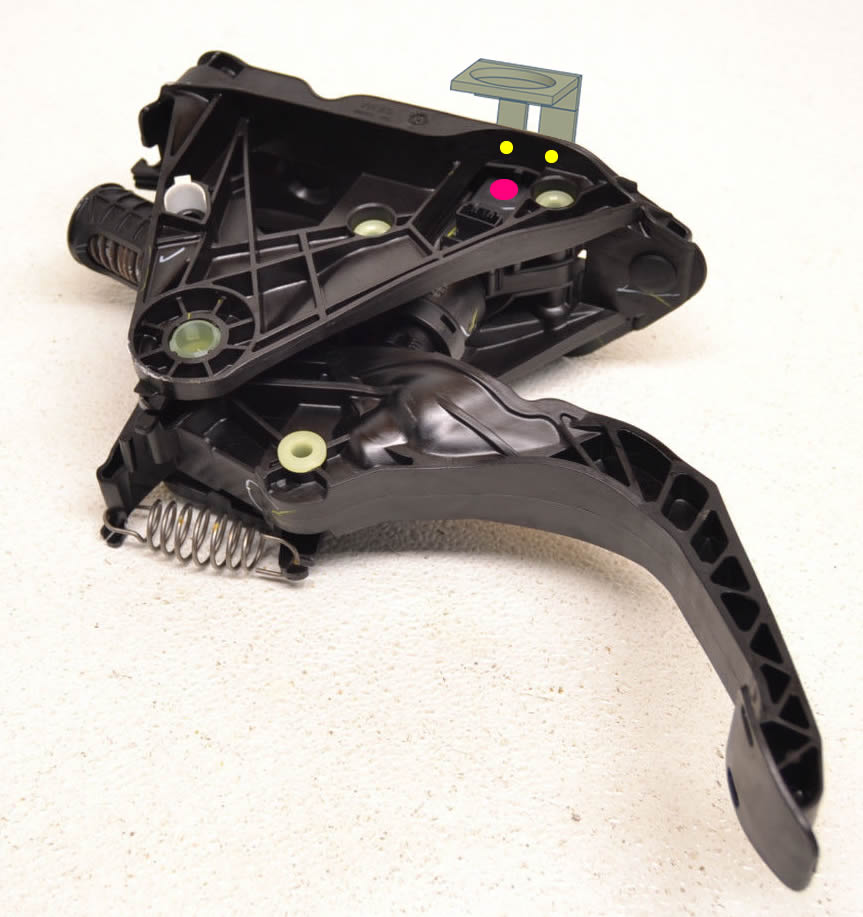

Here's some pics for everyone else to show where you're trying to get the magnet to go, and how to know where the mount goes.

The pink circle is where the magnet needs to end up to start the car. As close as possible flat against that exact spot.

The yellow dots are where you drill the holes for mounting.

Next...

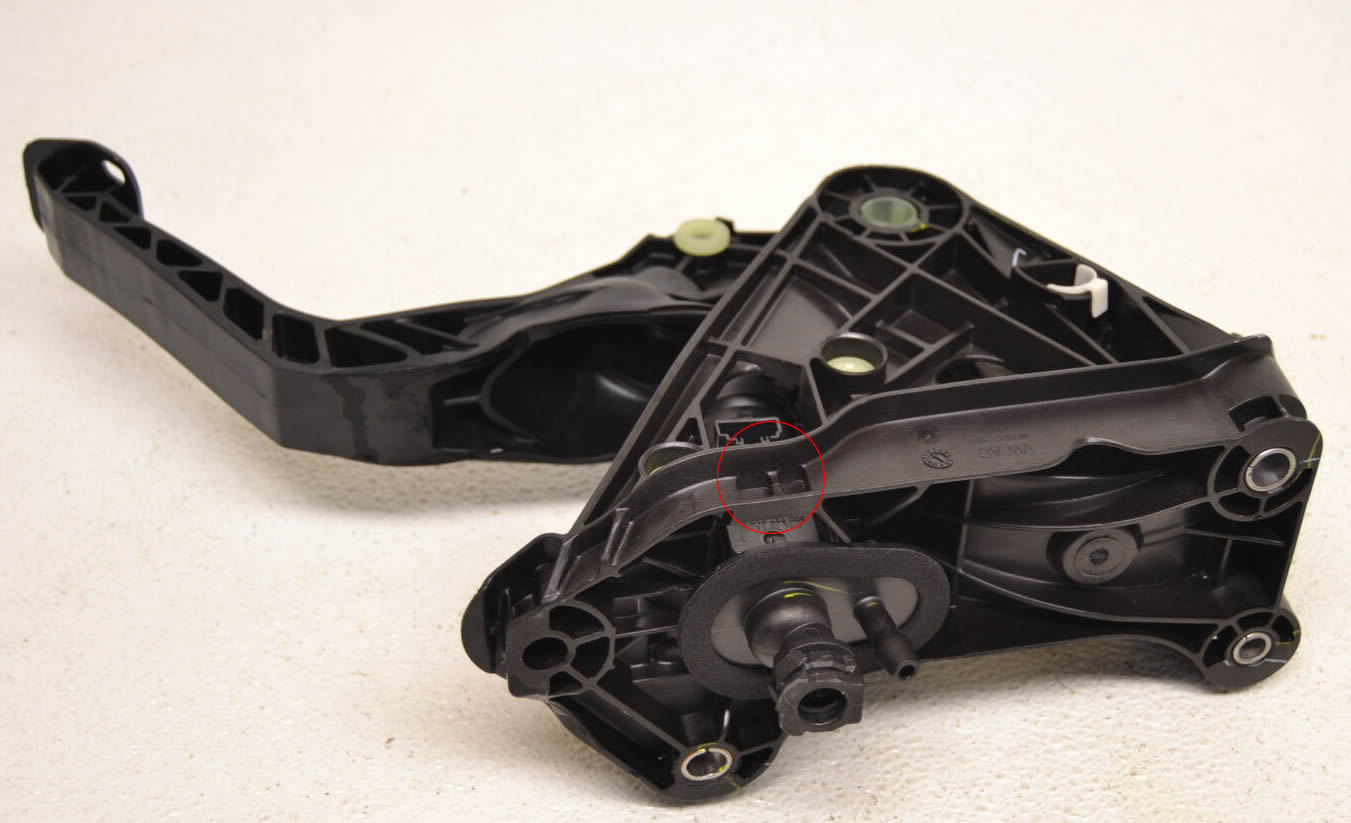

The red circle shows where the two tongues of the mount slide into. VW was very kind in providing these little indentations to serve as a guide.

And here's a final mockup showing more or less where the mount ends up.

You may be wondering how the mount is actually held on with the bolts - how you get the nuts in there. You'll have to *carefully* epoxy the nuts onto the back of the mount in the right place and let dry before install. That way they will already be in the right place for the little m3 screws to thread in. Another warning, it's a bitch to hold the rig in place with one hand and use a long allen key with the other.

More to come.

Here's some pics for everyone else to show where you're trying to get the magnet to go, and how to know where the mount goes.

The pink circle is where the magnet needs to end up to start the car. As close as possible flat against that exact spot.

The yellow dots are where you drill the holes for mounting.

Next...

The red circle shows where the two tongues of the mount slide into. VW was very kind in providing these little indentations to serve as a guide.

And here's a final mockup showing more or less where the mount ends up.

You may be wondering how the mount is actually held on with the bolts - how you get the nuts in there. You'll have to *carefully* epoxy the nuts onto the back of the mount in the right place and let dry before install. That way they will already be in the right place for the little m3 screws to thread in. Another warning, it's a bitch to hold the rig in place with one hand and use a long allen key with the other.

More to come.