7

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printer & C.A.D. Thread

- Thread starter GolNat

- Start date

AzteCypher

Go Kart Champion

- Location

- Austin, TX

- Car(s)

- Mk7 Golf R

I use CHEP's profiles and don't change the speeds he's assigned to his profiles. They've worked pretty well for me thus far. I tend to tweak infill and wall numbers to see differences in print times.

Rollux

Ready to race!

- Location

- New Zealand

- Car(s)

- Mk7 1.4TSi

0.6mm nozzle is great for speed if you’re doing lots of straight stuff or things without too much detail.

my ender pro is usually 25mm first layer, 75mm outer walls and top, 98mm for the rest, on a 0.6 nozzle.

my ender pro is usually 25mm first layer, 75mm outer walls and top, 98mm for the rest, on a 0.6 nozzle.

AzteCypher

Go Kart Champion

- Location

- Austin, TX

- Car(s)

- Mk7 Golf R

Finally finished my design. It will (hopefully) be a sponge holder for the kitchen sink. According to Cura, it'll take one day and 6hrs. We'll see if my design is good after 3 redesigns.

dtfd

Autocross Champion

- Location

- Massachusetts

- Car(s)

- MK7.5 GTI

I need to start playing with the speed between first layers/walls/infill.

I've just been just leaving my speed the same throughout.

I've just been just leaving my speed the same throughout.

Acadia18

Autocross Champion

- Location

- The Greater Boston Metropolitan Area

- Car(s)

- 2019 Golf R

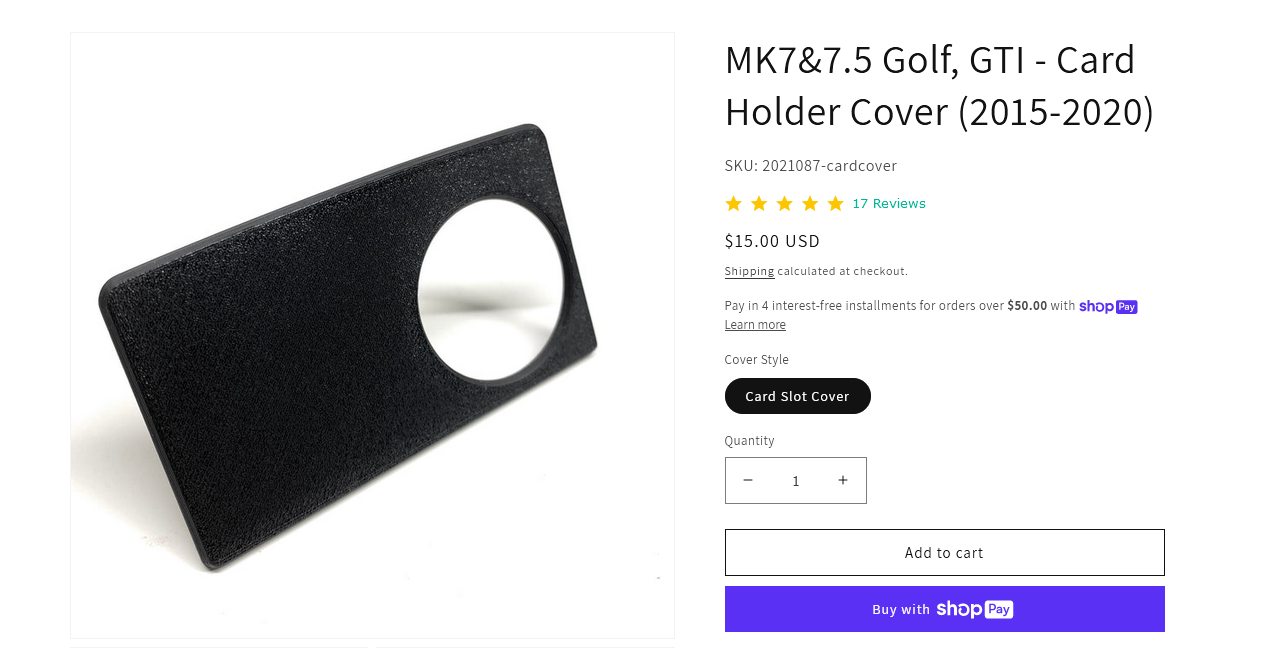

One of y'all needs to print this

https://www.printables.com/model/379772-no-3-rubber-band-gun-with-mag

https://www.printables.com/model/379772-no-3-rubber-band-gun-with-mag

One of y'all needs to print this

https://www.printables.com/model/379772-no-3-rubber-band-gun-with-mag

That is badass!!

My laptop won’t load printables cause it’s so old

I need to start playing with the speed between first layers/walls/infill.

I've just been just leaving my speed the same throughout.

I started to then stopped myself from going down the speed rabbit hole…for now anyway.

Direct drive, better heat break, all metal hot end.

dtfd

Autocross Champion

- Location

- Massachusetts

- Car(s)

- MK7.5 GTI

Has anyone built an enclosure for their printer? My printer is sitting in a bit of a drafty room so I'm thinking of building an Ikea Lack enclosure. I'm getting tired of bigger prints lifting a corner because a cool breeze is causing the plastic to cool too quickly. (My theory, but not totally crazy since it happens on the same drafty corner each time it happens)

I've got some questions about building an enclosure:

Do I need to move the PSU to outside the enclosure?

From what I've heard the temps inside an enclosure are bad for the PSU so I'll need to relocate it. From what I can tell with the Ender 3 V2 Neo it looks like my PSU is wired directly in rather than having an easy connector that I can just get an extension for. I've never soldered wires so I'll learn if I absolutely have to, but I'd rather not risk cooking my board because I don't know what I'm doing. (This is information from the internet, I haven't yet removed the cover and checked)

Should I move anything else out of the enclosure?

I've got a micro SD to SD extender that will be mounted outside the enclosure so I can easily access the memory card and I don't wear out the mirco SD reader on the printer itself. Should I get an extender and move my screen to outside the enclosure as well? Does it matter?

Should I future proof now and get a fan built into the enclosure?

I don't plan on printing in ABS since it's not a great thing to do in a space you live in. I know the reason most people build an enclosure to begin with is in order to print with ABS. Should I future proof the build and plan for a fan system in there, or should I cross that bridge when and if I get to it? Will having a fan keep temps inside the enclosure down to the point where I wouldn't need to relocate the PSU, or would having a fan that strong create the same issue I'm building this enclosure to avoid?

I've got some questions about building an enclosure:

Do I need to move the PSU to outside the enclosure?

From what I've heard the temps inside an enclosure are bad for the PSU so I'll need to relocate it. From what I can tell with the Ender 3 V2 Neo it looks like my PSU is wired directly in rather than having an easy connector that I can just get an extension for. I've never soldered wires so I'll learn if I absolutely have to, but I'd rather not risk cooking my board because I don't know what I'm doing. (This is information from the internet, I haven't yet removed the cover and checked)

Should I move anything else out of the enclosure?

I've got a micro SD to SD extender that will be mounted outside the enclosure so I can easily access the memory card and I don't wear out the mirco SD reader on the printer itself. Should I get an extender and move my screen to outside the enclosure as well? Does it matter?

Should I future proof now and get a fan built into the enclosure?

I don't plan on printing in ABS since it's not a great thing to do in a space you live in. I know the reason most people build an enclosure to begin with is in order to print with ABS. Should I future proof the build and plan for a fan system in there, or should I cross that bridge when and if I get to it? Will having a fan keep temps inside the enclosure down to the point where I wouldn't need to relocate the PSU, or would having a fan that strong create the same issue I'm building this enclosure to avoid?

AzteCypher

Go Kart Champion

- Location

- Austin, TX

- Car(s)

- Mk7 Golf R

One of y'all needs to print this

https://www.printables.com/model/379772-no-3-rubber-band-gun-with-mag

I need to give this one a go when I'm done with my current print. This will really annoy my wife.

Has anyone built an enclosure for their printer?

I know you said you think you'd never want to print in ABS, but this video alleviated my ABS corner lifting issues. About 1:56 into the video is when you see what changes he made to his printer.

While I'm not sure this will alleviate your corner lifting issues (as his method tends to block all air flow onto the print and assumes you're not printing with the fan on) it might be something to think about in regards to your corner lifting issue.

As far as an enclosure to block drafts, I slid a large box over my printer to block everything except the top when I was first trying to figure out how to print ABS. You could try this out first before spending money on a good enclosure. If you find that it helps, then you can figure out something nicer.

jawndropper

Drag Racing Champion

- Location

- Tysons, VA

- Car(s)

- 2017 GTI Sport

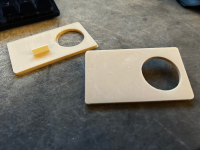

I am trying to recreate a coin slot cover.

I've never used CAD before but I whipped this up in 30 minutes last night. The design is far from perfect and I have some printer issues to work out but I am off to a good start.

View attachment 271623

Once I figure out what Im doing in Fusion 360, I will post the STL file here.

I've never used CAD before but I whipped this up in 30 minutes last night. The design is far from perfect and I have some printer issues to work out but I am off to a good start.

View attachment 271623

Once I figure out what Im doing in Fusion 360, I will post the STL file here.

Attachments

jawndropper

Drag Racing Champion

- Location

- Tysons, VA

- Car(s)

- 2017 GTI Sport

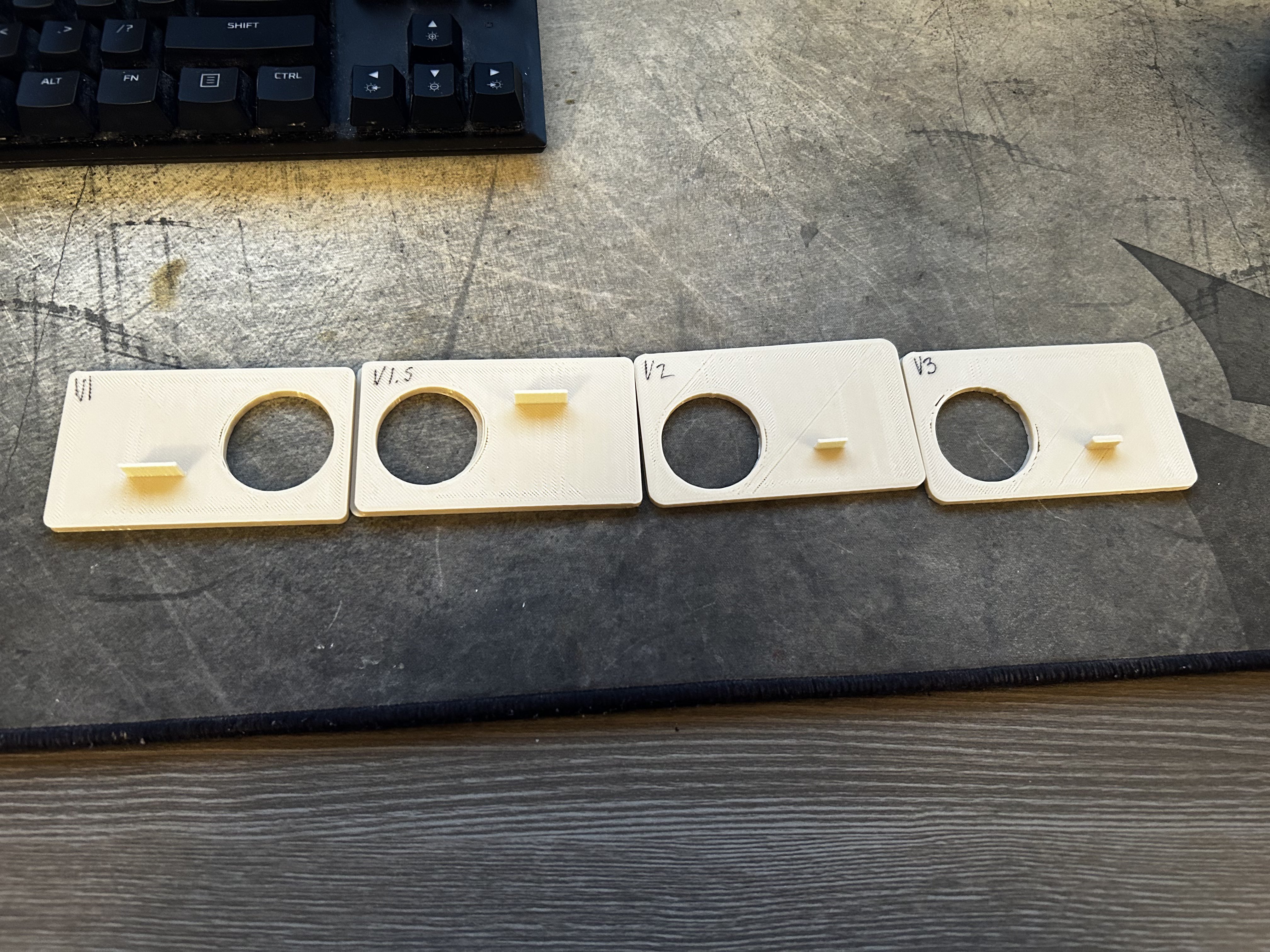

i absolutely suck at CAD but am making progress with the coin slot cover  fortunately these only take about 45 minutes to print.

fortunately these only take about 45 minutes to print.

Not sure where to start diagnosing why my circles arent printing right

Not sure where to start diagnosing why my circles arent printing right

i absolutely suck at CAD but am making progress with the coin slot coverfortunately these only take about 45 minutes to print.

View attachment 271683View attachment 271684

Not sure where to start diagnosing why my circles arent printing right

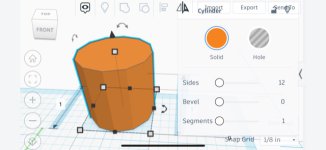

In the settings for the circle/hole shape, increase sides.

This is the setting in tinkercad.

This will decrease the length of the line segments that form the curve, therefore “smoothing” the line out.

your top layering looks light. Maybe increase your nozzle temp or decrease cooling fan for the layer. Also might want to try playing with your z-offset in .01mm increments to get better fill.

Last edited: