Maybe I don't understand what you are referring to when you say brake dive, but wouldn't brake dive be more of a function of suspension geometry not pad compound? or even shock tuning? I know for mountain bikes fork tuning and even rear suspension design has a big influence on anti-squat and brake dive. Even my RC cars have suspension settings for more or less dive.

7

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2017 GTi PP at VIR

- Thread starter Mini7

- Start date

DerHase

Autocross Champion

- Location

- Hampton Roads, VA

- Car(s)

- 2019 GTI Rabbit

ABS just keeps it from staying locked. Fronts will lock and unlock repeatedly. Car dances around a bunch as this happens.ok, uneven brake force front to rear. But wouldn't the ABS prevent locking? Just trying to understand.

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

I have 500lbs springs in the front and I can still easily overpower them. Despite being 3-clicks from hard on my Ohlins. Yes preventing the front end diving under braking can be tuned out with stiffer springs and shocks.

So when the front of the car dives under hard braking the rear end rises losing rear grip contributing to the rear instability making it harder to compress the brake zones. By going to a more aggressive rear pad we move some of the brake bias rearwards. This should reduce some of the front end dive and improve overall grip under braking, allowing you to brake deeper.

So when the front of the car dives under hard braking the rear end rises losing rear grip contributing to the rear instability making it harder to compress the brake zones. By going to a more aggressive rear pad we move some of the brake bias rearwards. This should reduce some of the front end dive and improve overall grip under braking, allowing you to brake deeper.

xXDavidCXx

Autocross Champion

- Location

- AZ

- Car(s)

- 2017 GTI SE DSG

To be clear shocks are only a timing device, and cannot control overall suspension movements, just slows them down. Given enough time, all suspensions will max compress.I have 500lbs springs in the front and I can still easily overpower them. Despite being 3-clicks from hard on my Ohlins. Yes preventing the front end diving under braking can be tuned out with stiffer springs and shocks.

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

@xXDavidCXx Yes, you are correct.

The discussion has centered on a very specific issue on tuning brake performance on our very forward biased brake systems. This applies to improving stock PP brakes on track as well as BBK equipped cars.

One is to remove some of the heat generated by the front brakes to increase pad/rotor life by moving some more braking rearward. Important on for stock PP brakes. The other is to improve overall brake performance. This needs to be balanced carefully as not to impact trail-braking negatively.

For me it’s about improving overall brake balance front to rear and improving the rear instability Im experiencing. So I can continue running zero rear toe which has other benefits and go back to braking deeper in the big brake zones at VIR.

The discussion has centered on a very specific issue on tuning brake performance on our very forward biased brake systems. This applies to improving stock PP brakes on track as well as BBK equipped cars.

One is to remove some of the heat generated by the front brakes to increase pad/rotor life by moving some more braking rearward. Important on for stock PP brakes. The other is to improve overall brake performance. This needs to be balanced carefully as not to impact trail-braking negatively.

For me it’s about improving overall brake balance front to rear and improving the rear instability Im experiencing. So I can continue running zero rear toe which has other benefits and go back to braking deeper in the big brake zones at VIR.

DerHase

Autocross Champion

- Location

- Hampton Roads, VA

- Car(s)

- 2019 GTI Rabbit

Yep. Also if you're able to utilize 100% of the rear brakes abilities (limited by rear tire grip/weight transfer dynamically way more than the front), then it also has the effect of keeping the chassis straight(er) under braking. Just like how accelerating straightens the car when sideways. Very similar forces at play trying to work on the entire chassis but originating at only one end.

There are forces at play in regards to antisquat and antidive so adding more braking force (out back) should change the effects of those as well. I'm not as familiar with those effects on IFS/IRS stuff, moreso 4 linked 4wd stuff. The suspension acts VERY differently under braking in 4wd(fully locked front rear and center) vs 2wd. This is because no matter what your braking(and engine power) is 50% split front to back regardless of what you've done while in 4wd. Add more rear brake bias and those two examples act a lot closer to each other.

I don't think the front brake heat difference will be noticeable, as it'll only allow you to push even harder now.

Still, a win

/End overthinking

There are forces at play in regards to antisquat and antidive so adding more braking force (out back) should change the effects of those as well. I'm not as familiar with those effects on IFS/IRS stuff, moreso 4 linked 4wd stuff. The suspension acts VERY differently under braking in 4wd(fully locked front rear and center) vs 2wd. This is because no matter what your braking(and engine power) is 50% split front to back regardless of what you've done while in 4wd. Add more rear brake bias and those two examples act a lot closer to each other.

I don't think the front brake heat difference will be noticeable, as it'll only allow you to push even harder now.

Still, a win

/End overthinking

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

@DerHase, I got some advice that the DS3000 may not be a good rear pad option because of the steeply rising Mu curve. The DS1.11 is better suited on a rear axle FWD car.

Which you already know from Alex’s experience at VIR. Does Alex post any GoPro video on YouTube?

That Mu curve is flat and declining. Will be interesting to see the rear temp paint on my rear rotors When I’m back at VIR.

Which you already know from Alex’s experience at VIR. Does Alex post any GoPro video on YouTube?

That Mu curve is flat and declining. Will be interesting to see the rear temp paint on my rear rotors When I’m back at VIR.

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

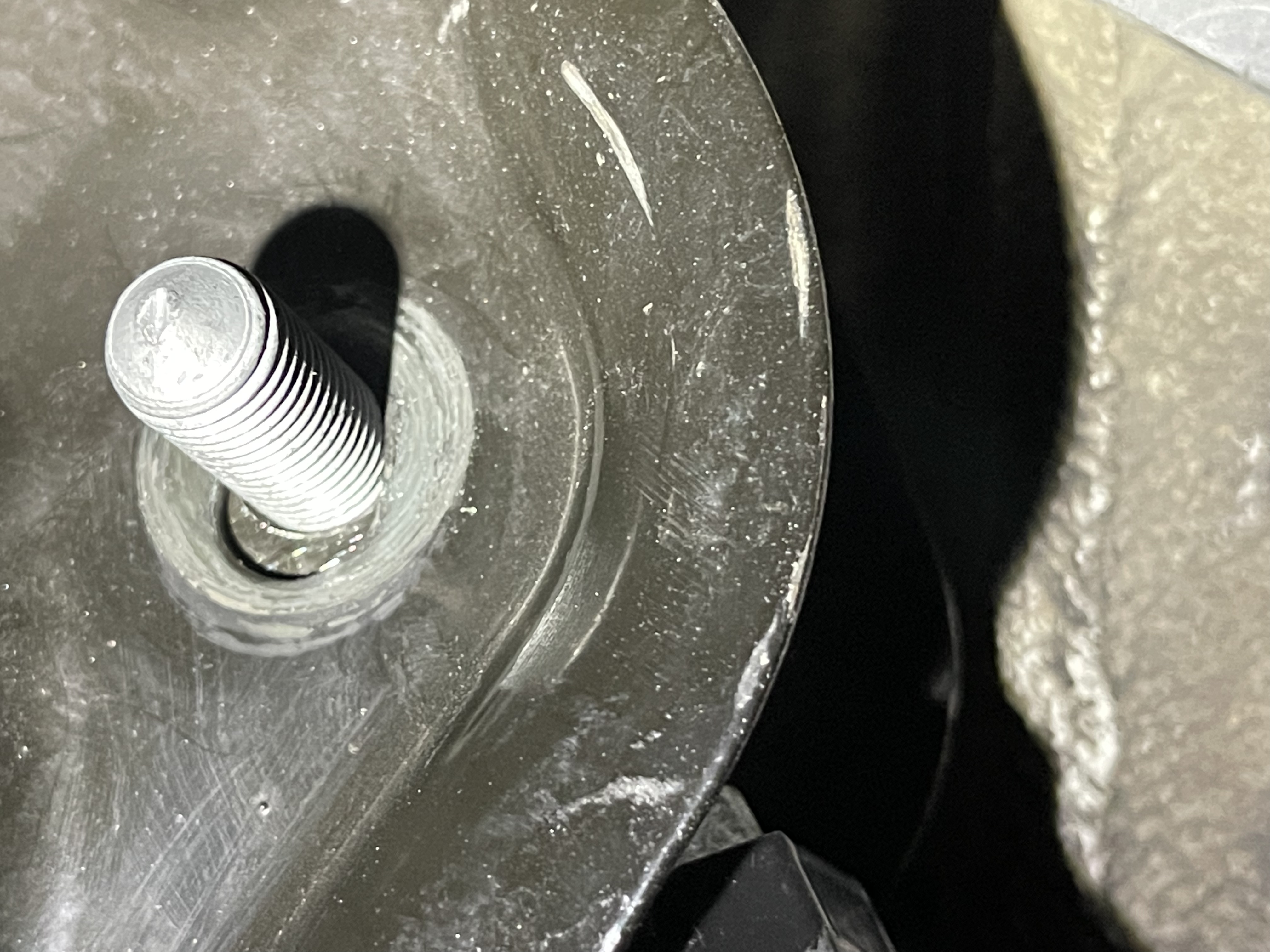

GTi Subframe Caster Adjustment

I meant to post this earlier. I will update my Verkline front LCA install doc. There is some Caster adjustment in the slotted hole in the front subframe. I first noticed this when installing my Verkline LCA’s. Move to the most forward position to add Caster, Its about 4mm so I am guessing about .5 to .75 degrees of additional Caster.

I meant to post this earlier. I will update my Verkline front LCA install doc. There is some Caster adjustment in the slotted hole in the front subframe. I first noticed this when installing my Verkline LCA’s. Move to the most forward position to add Caster, Its about 4mm so I am guessing about .5 to .75 degrees of additional Caster.

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

Verkline Rear LCA Bearing

I installed Verklines rear LCA bearings into a spare set of rear LCA’s. I used my OTC C-Clamp press out the stock bushings. After trying this once before when trying to install my current SuperPro bushes, I ended up taking it to a machine shop to press the cocked stock bushing and to press in the SuperPro units. The problem is the split stamped steel bearing cup/housing in the LCA. It flexes and makes the job difficult.

This time round I used a piece of 3/4” aluminum flat bar as a spacer to prevent the two separate cups from flexing. Ideally you need a 21mm wide piece of flat bar to wrap around the bushing housing to support it while pressing out the bushing and then pressing in the Verkline bearings. My sleeve cup barely cleared the Verkline aluminum bearing housing which made the last few mm tricky. If you have a 46mm ID sleeve it will be easier. Using some sort of spacer is the key to making this an easy install.

I installed Verklines rear LCA bearings into a spare set of rear LCA’s. I used my OTC C-Clamp press out the stock bushings. After trying this once before when trying to install my current SuperPro bushes, I ended up taking it to a machine shop to press the cocked stock bushing and to press in the SuperPro units. The problem is the split stamped steel bearing cup/housing in the LCA. It flexes and makes the job difficult.

This time round I used a piece of 3/4” aluminum flat bar as a spacer to prevent the two separate cups from flexing. Ideally you need a 21mm wide piece of flat bar to wrap around the bushing housing to support it while pressing out the bushing and then pressing in the Verkline bearings. My sleeve cup barely cleared the Verkline aluminum bearing housing which made the last few mm tricky. If you have a 46mm ID sleeve it will be easier. Using some sort of spacer is the key to making this an easy install.

DerHase

Autocross Champion

- Location

- Hampton Roads, VA

- Car(s)

- 2019 GTI Rabbit

@DerHase, I got some advice that the DS3000 may not be a good rear pad option because of the steeply rising Mu curve. The DS1.11 is better suited on a rear axle FWD car.

Which you already know from Alex’s experience at VIR. Does Alex post any GoPro video on YouTube?

That Mu curve is flat and declining. Will be interesting to see the rear temp paint on my rear rotors When I’m back at VIR.

Yeah I'm skeptical of the 3000s, but unless I want to swap/code the electronic parking brake calipers from the R, the 3000s are the only rear Ferodo option for the GTI calipers.

I don't think he shares videos online but I'll ask when I see him next.

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

Its a helpful reference point if he posts on YouTube. Especially if he has data overlaid onto the video.

I will reach out to EssexParts and ask about doing a group buy for the PP GTi’s. That may prompt them into a production run. They already have the backing plates for the DS2500/3000’s.

Once I get these rear LCA’s on, every bushing will have been replaced with a spherical bearing.

I will reach out to EssexParts and ask about doing a group buy for the PP GTi’s. That may prompt them into a production run. They already have the backing plates for the DS2500/3000’s.

Once I get these rear LCA’s on, every bushing will have been replaced with a spherical bearing.

Mini7

Autocross Champion

- Location

- Charlotte, NC

- Car(s)

- 2017 GTi Sport PP

OBD Dongles?

Has anyone used Vbox/Racelogics OBD Dongle to capture engine data to overlay onto GoPro video?

https://www.vboxmotorsport.com/store/index.php?route=product/product&product_id=129

Vbox makes good data loggers, so I am hoping this unit is decent quality and will pair with Track Addict to capture some basic engine functions.

What are folks using to capture additional engine data? OBD11 is too cumbersome to use at the track.

Has anyone used Vbox/Racelogics OBD Dongle to capture engine data to overlay onto GoPro video?

https://www.vboxmotorsport.com/store/index.php?route=product/product&product_id=129

Vbox makes good data loggers, so I am hoping this unit is decent quality and will pair with Track Addict to capture some basic engine functions.

What are folks using to capture additional engine data? OBD11 is too cumbersome to use at the track.